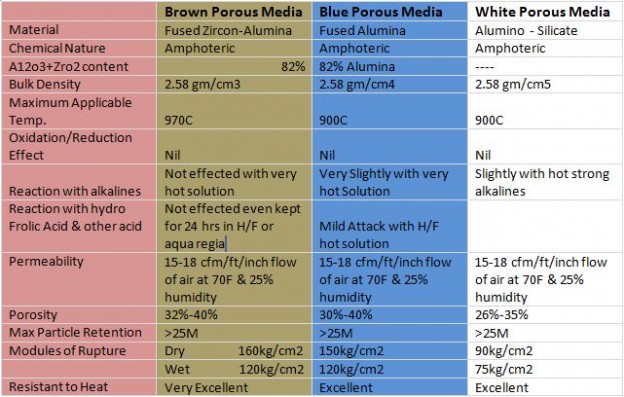

Shree Krishna has introduced a breakthrough technology in porous media by introducing Fused Zircon with conventional Fused Alumina.

To seperate the suspended particles from alkaline, acid or other corrosive liquids & gases etc. it leads to a high degree of abrasion & the right combination of Zircon & alumina gives enhanced properties such as high refractories, high resistance to thermal fatigue, high resistance to abrasion, corrosion, thermal stability, enhanced life and other refractory properties.

SKC Porous media is stable up to 970 degree centigrade & even at high temperature it remains stable as Zircon is very much chemically inert, and has no reaction with majority of acids & alkalls, and stable at higher temperature.

With our revolutionary breakthrough technology and R&D we have developed and are the only manufacturers for Zirconia Fluidisng Pads, which are far superior to the conventional Alumina Fluidising pads.

Zircon has higher abrasive properties and gives much longer life and acts as an NRV in ash handling systems in Thermal Power Plants.

Zirconia is highly stable and its high corrosion resistance gives better performance in chemical treatments and filration.

Chemical & Physical Specs

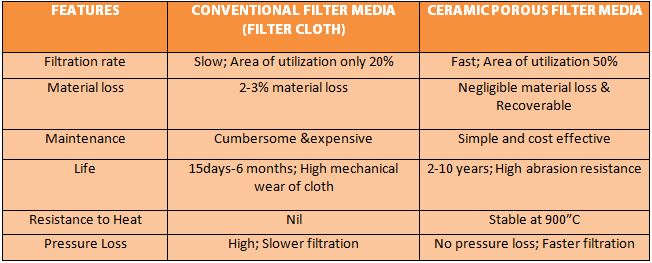

BENEFITS OF CERAMIC POROUS FILTER MEDIA

Application

SKC product is matchless & stable above the conventional Alumina tiles & it is the most cost- effective product with better technology & life. This revolutionary development finds its application with Cement silos and Ash handling in thermal power plants. Also in aeration & neutralization in Effluent treatment Plants & Fluidization in Boilers.It also has a vast application in Chemical & Dyestuff, Fertilizer,Refineries, Petrochemicals, Cement, Distilleries.

SKC products are made in various sizes & shapes & we make tailor made shapes & sizes required in different grade of porosity & permeability to suit the diversified needs & application of our esteemed customers.

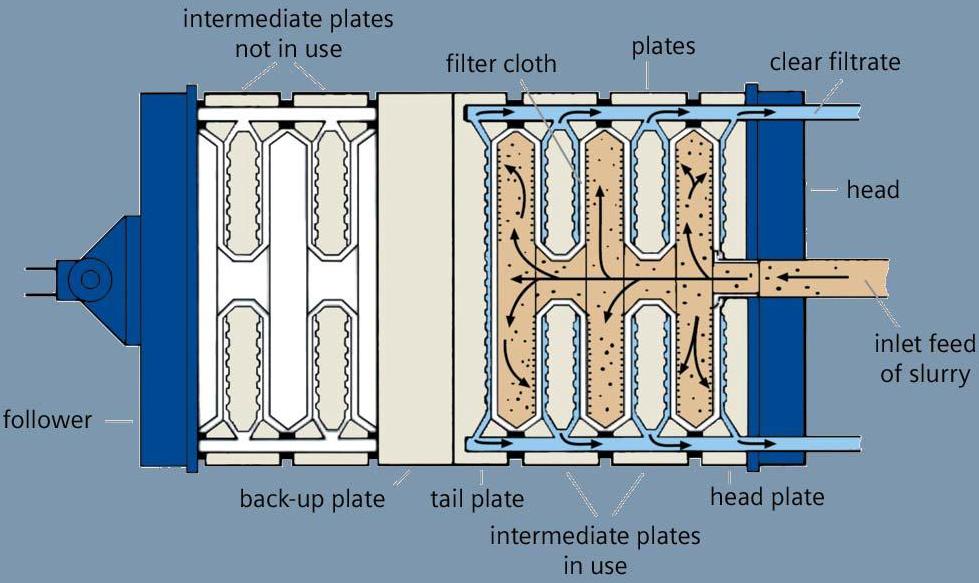

HOW IT WORKS

The slurry which is to be filtered is poured on to the ceramic Porous Tile fitted in the bottom of the filtering chamber. The Porous media allows the liquid(filtrate) to pass through to the bottom of the tank, while the solid(substrate) remain on its surface, Pipes then carry the filtered liquid away.

In ash handling plants the ash gets collected on the porous tile fitted in the silos. The Porous tile allows the pressurized air applied from the bottom of the tank to pass through resulting in suspension of ash which gets channeled to the outlet.